Processed recycled fibres pose fewer challenges: Swiss firm Uster

Insights

- Uster Technologies explored the processing of recycled fibres, noting they pose fewer challenges compared to new materials in its Sustainability Bulletin.

- It guides yarn producers on handling recycled fibres, suitable for clothing like T-shirts.

- The bulletin addresses issues in spinning recycled materials, particularly their limitations in quality.

It is true that recycled yarns have limitations in terms of yarn fineness. Uster’s Sustainability Bulletin is focused on the more problematic recycled raw material. For example, it deals with the potential difficulties in the various process steps in spinning, Uster Technologies said in a press release.

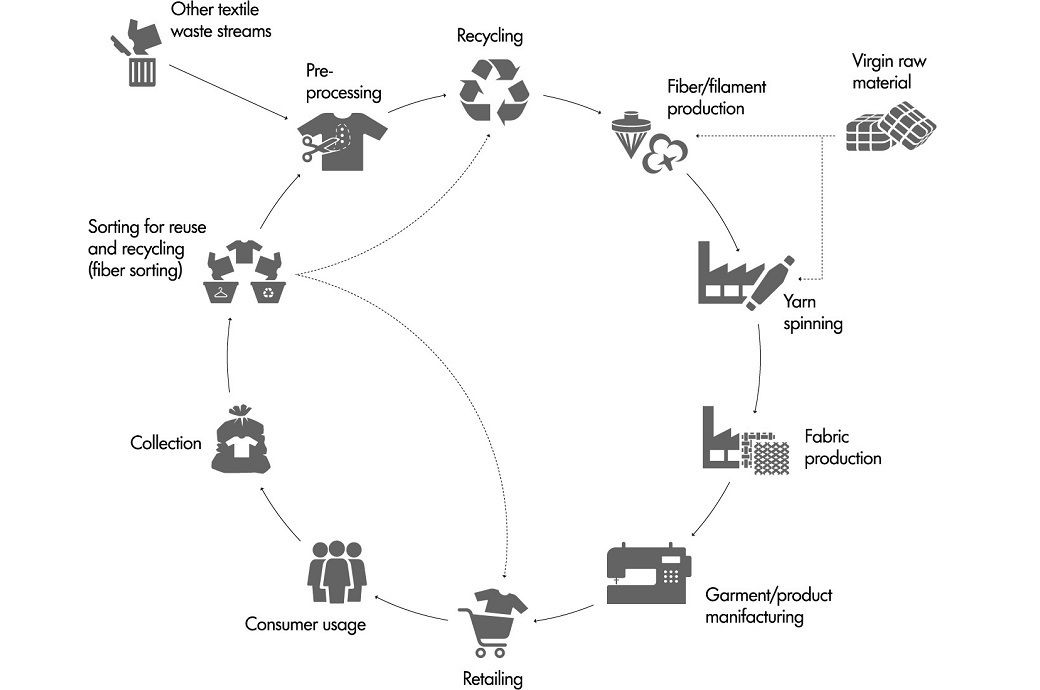

Uster Technologies covers the whole story of recycled textile materials in its application report Sustainability Bulletin No. 1. The publication is part of Uster’s commitment to support the use of recycled materials along the entire textile value chain.

Many consumers today already expect recycled materials to be used in the clothing and home textiles they purchase—and this is clearly pushing innovation throughout the industry. However, there is a degree of uncertainty about what this trend means for yarn producers, both economically and technically. The first Uster Sustainability Bulletin outlines the challenges and presents the solutions.

Upstream in textile processing, spinners are often asked to produce yarns with recycled materials, with comparable quality to those from new fibre.

“The use of mechanically recycled fibres in spinning has specific quality considerations. Such fibres have a higher short-fibre and nep content and may often be coloured, particularly if post-consumer material is used,” said Gabriela Peters, head of product management laboratory systems at Uster Technologies and one of the bulletin’s authors.

Studies have shown that yarns and fabrics produced from recycled fibres may be better for applications where the strength of yarns and fabric is less critical, but where control of unevenness, imperfections, and handle properties is required. Consequently, recycled fibres are most suitable for manufacturing casual clothes such as T-shirts, sweatshirts, and sleepwear. In China, tons of denim jeans trousers are already made of mechanically recycled fibres.

Uster Technologies sees its role as knowledge provider, setting definitions and standards, to accelerate this ongoing industry transformation. As a long-term trusted supplier of quality control systems to the textile manufacturing industry, Uster assists the industry by evaluating test results. This helps to guide spinners on the current possibilities for dealing with recycled material in its many forms.

The Uster Statistics benchmarks will be helpful in the requirement to measure, control, and improve the quality. The new edition, launched at ITMA 2023, includes for the first time a section for recycled yarn. The Uster Statistics 2023 edition also features an extended range of fibre data, supporting sustainability goals. It’s a fact that an ideal fibre mix—with or without recycled content—must also meet quality requirements for minimal waste.

Uster understands its function as a kind of neutral arbiter, reporting what quality can be expected when processing different recycled materials.

Using recycled materials effectively and efficiently will be a key to success in future years. To achieve acceptable results and profitability, all sections of the textile chain will need to cooperate and learn from each other, to avoid collective failure.

“At Uster Technologies, we firmly believe it’s a great opportunity for textile manufacturers to lead this momentous industry transformation, as recycled fibres are the raw material of a sustainable future to be processed into new products,” added Peters.

Fibre2Fashion News Desk (NB)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)