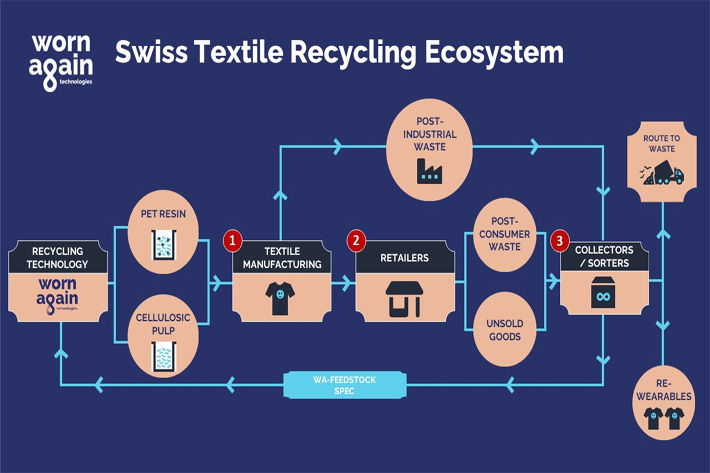

The Swiss Textile Recycling Ecosystem is a network comprising fabric and textile manufacturers, waste collectors and sorters, as well as retailers, brand owners and technology providers. To cause a paradigm shift in the fashion industry and realise true circularity requires all members of the value chain to be on the same page and working towards the same goals. All these parties will cooperate to make their shared sustainability vision for the sector a reality, WAT said in a press release.

The partners will provide different types of textile waste to WAT’s demonstration plant, which will process 1000 tonnes of material per year and is being built near the WAT’s technology scale-up partner, Sulzer Chemtech. After advanced chemical processing, virgin-like recycled fibres, such as polyethylene terephthalate (PET) and cellulose, will be provided to the same industry players to produce new high-quality fabrics.

More precisely, the consortium will be composed of WAT’s main shareholders, Sulzer, Oerlikon, and H&M group. In addition, Rieter will support short-staple spinning, Monosuisse will take care of PET fibre production, Coop will act as retailer, TEXAID will manage collection, sorting, and provide feedstock together with Sallmann (ISA) and Serge Ferrari – all coordinated by Swiss Textiles.

The creation of Swiss Textile Recycling Ecosystem marks a key milestone in the upscaling of WAT’s recycling process technology. It also supports its ambition to create a circular economy where non-reusable, hard-to-recycle textiles can be reintroduced into supply chains to become new fibres, textiles and other products, according to WAT.

The construction of WAT’s first demonstration plant will start this year in Winterthur, Switzerland. This represents a crucial step towards upscaling and commercialising the company’s recycling process technology.

“Launching the Swiss Textile Recycling Ecosystem is a vision coming true. This leading group of likeminded organisations will help to shift the fashion industry from traditional, linear product lifecycle models to eco-conscious, circular material management. We believe that zero waste strategies can only become a reality if the entire sector is committed to acting as a whole. We see the Ecosystem as a way to align sustainability efforts across the whole textile value chain and as the next step towards a green fashion industry,” Erik Koep, CEO at WAT, said in a statement.

“We look forward to working together with all members of the Swiss Textile Recycling Ecosystem. Their support is extremely valuable and their trust in our project is much appreciated. The Ecosystem members will support our textile recycling demonstration facility by providing textile waste that can be used as feedstock. The collaboration will also play a key role in scaling up our capabilities and building a network to support the implementation of industrial-scale plants globally,” Torsten Wintergerste, chairman of WAT and division president at Sulzer Chemtech, said.

Fibre2Fashion News Desk (GK)