Luwa's LoomSphere empowers weaving mills for a profitable future

Insights

- Luwa has introduced LoomSphere System, enhancing weaving mill efficiency with features like laminar airflow, direct conditioning, and efficient dust removal.

- Championing Swiss Quality, LoomSphere is aimed at reducing yarn breakage and downtime.

- With up to 40% energy savings and an improved working environment, it sets new standards in weaving technology.

LoomSphere: Engineered for Excellence

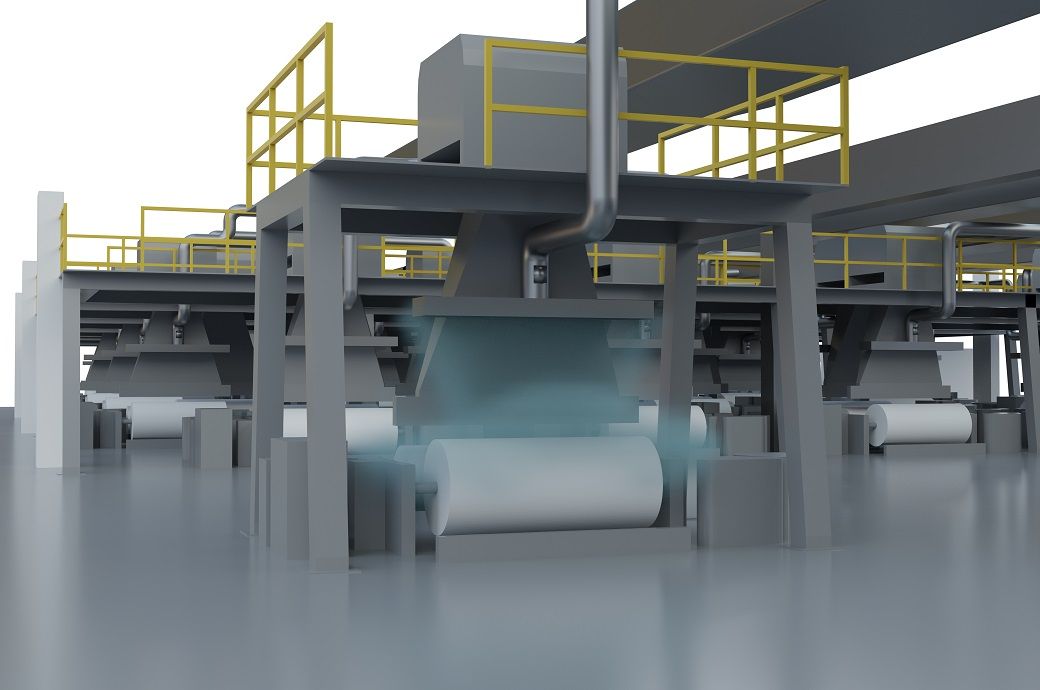

Profitability in weaving mills depends on the efficiency of weaving looms, which is significantly affected by downtime due to yarn breakage. Luwa recognises the critical role that environmental factors play in reducing yarn breakage, with particular emphasis on the importance of relative humidity. Through extensive research and innovation, Luwa introduces the LoomSphere System to overcome these challenges and raise weaving loom efficiency to unprecedented levels.

Key Features: Revolutionising Weaving Conditions

- Laminar Airflow: Clean air is supplied directly into the weaving zone, ensuring a precise working environment free from contaminants.

- Direct Conditioning: High humidity is delivered precisely where it is needed, optimising yarn strength, and minimising yarn breakage.

- Efficient Dust Removal: High air changes effectively eliminate dust from the weaving zone, maintaining cleanliness and enhancing productivity.

Optimising Air Conditioning for Weaving Efficiency

The LoomSphere System employs a targeted approach to air conditioning, focusing on high air changes and humidity control specific to the weaving process. By strategically installing the LoomSphere diffuser above the weaving loom, Luwa achieves optimal air distribution and humidity levels critical for uninterrupted operation.

Paving the Way Forward: Statement by Praveen Kumar Singh, Managing Director, Luwa India

“At Luwa, we are committed to providing innovative solutions to the textile industry. The LoomSphere System represents a paradigm shift in the management of weaving processes and offers unprecedented efficiency and productivity gains. With our commitment to Swiss Quality Air Engineering since 1935, we are proud to offer this revolutionary system. We are convinced that it will enable weaving mills to increase their performance and competitiveness.”

Luwa’s Commitment to Efficiency

Luwa’s LoomSphere System is designed to maintain the weaving environment at peak efficiency, minimising the buildup of fibre fly in the loom shed area and maximising yarn strength. The system’s patented local displacement air outlet ensures low-turbulence airflow, maintaining ideal conditions up to the warp and capturing exhaust air, dust, and fibre fly directly under the weaving machine.

Setting New Benchmarks: The LoomSphere Advantage

- Enhanced Operator Comfort: By efficiently removing heat and dust, the system creates a comfortable working environment for operators.

- Significant Energy Savings: With a 40 per cent reduction in energy consumption compared to conventional systems, the LoomSphere System ensures sustainable operations and reduced operational costs.

- Optimised Heat Dissipation: Aluminium profiles facilitate efficient heat dissipation, further enhancing overall performance.

The Luwa LoomSphere System sets a new standard in weaving technology, offering unparalleled efficiency, productivity, and sustainability. With its innovative design and tangible benefits, the LoomSphere System is poised to enable a future of seamless operations and improved profitability.

Engineering a Better Tomorrow with Luwa

From its groundbreaking beginnings in textile air conditioning and filtration, Luwa has transformed into a globally recognised leader in air engineering. For over 80 years, the company has championed Swiss Quality, delivering expert solutions across 60+ countries and various industries. Explore the future of energy-efficient textile manufacturing with Luwa’s Digital Solutions, encompassing groundbreaking systems for fine dust collection, waste collection, machine & room cleaning, humidification & cooling, temperature control, air distribution, control engineering, air handling unit housings, fans, spark detection, and more. Whether you specialise in spinning, weaving, nonwovens, diaper/feminine hygiene, or tissue paper, Luwa offers comprehensive solutions tailored to your needs. Join us in creating a sustainable future for all industries – let’s engineer a better tomorrow, together.

Fibre2Fashion News Desk (RKS)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)