BTMA's advanced fibre focus at Techtextil 2024 in Germany

Insights

- BTMA's focus on advanced fibres at Techtextil 2024 highlights the development of new fibres for various technical textile applications, meeting sustainability goals and enhancing performance.

- FET, a key member, specialises in multifilaments and nonwovens, with increased technical trials post-expansion.

- They focus on biopolymers, recycled fibres and more.

Many of them will be showcased at the forthcoming Techtextil 2024 exhibition which takes place in Frankfurt, Germany, from April 23-26.

The development of specific multifilaments, monofilaments and nonwovens for niche fibre applications – over 70 to date – is very much the specialist field of BTMA member Fibre Extrusion Technologies (FET), along with designing the bespoke fibre extrusion and spunbond and meltblown nonwoven systems to successfully produce them.

Following the opening of its expanded Fibre Development Centre with considerably enhanced facilities more than doubling capacity and increasing efficiency at the start of 2023, FET, which will be at stand A84 in Hall 12 at Techtextil has significantly accelerated the number of technical trials it has conducted for clients.

“We work closely in collaboration with customers ranging from huge multinationals to start-ups and spin-out companies,” explains FET managing director Richard Slack.

“At present we’re doing a lot of work with biopolymers and recycled fibres, because they all have different characteristics and behaviours and need specific handling and processing parameters, but we specialise in processing challenging materials.

“Another area we’re heavily involved in is in medical devices where there’s a lot of interest in resporbable products and how to influence absorption. Producers are looking at how to enhance the durability of implantables, for example, which would be advantageous in specific surgical procedures.

“In terms of new high performance products, one example we’re currently working on is hollow fibres, not from conventional polymers but from high temperature engineering polymers such as PEEK, as well as small scale nonwovens from engineered polymers for applications such as filtration.

“We’re also investigating the potential of certain olefins to achieve the high-strength and other desirable properties of ultra-high molecular weight polyethylene – UHMWPE. At present UHMWPE’s availability is dependent on being able to order in tons, but there is a lot of demand for lower quantities for tailored small-scale projects, and we see much potential in an olefin with a long molecular chain that we believe could potentially meet 80-90% of this market’s needs.”

Splicing

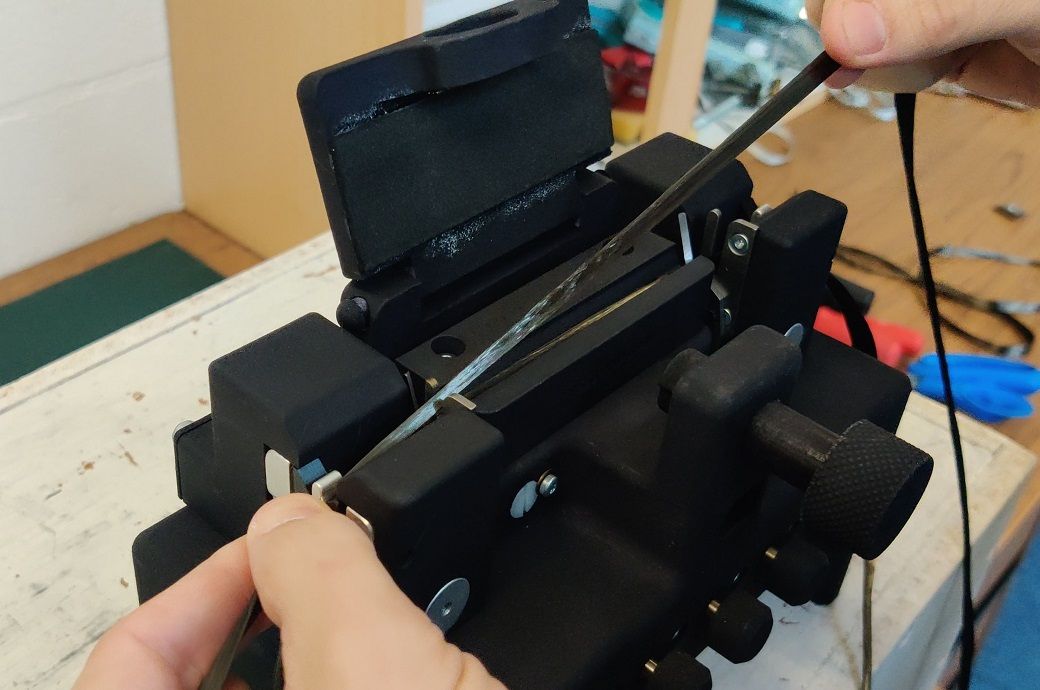

Resource efficiency in the processing of extremely expensive fibres like UHMPWE, or carbon and aramid, is a key benefit of the latest splicing technologies of Airbond (Hall 12, stand E31).

Pneumatic yarn splicing is a clever process established in the textile industry for joining yarns and works by intermingling individual filaments closely together, to make joint which are stronger and flatter than knots.

The patented splicers in Airbond’s latest range are 3D printed, making them both lighter and stronger, and now enable the splicing of yarns in sizes of up to 16,000 tex – compared to the 1,200 tex most splicing machines can handle.

“Understanding the physics behind splicing has enabled us to change the characteristics of the air in the splicing of fragile or ultra-large yarns,” explains Airbond research engineer Carwyn Webb. “We have increased the limits of normal splicers by a factor of ten, which will enable a huge reduction in expensive waste.”

Testing and fault detection

Sophisticated systems for the testing of fibres and advanced materials will also be showcased by BTMA members James Heal (Hall 12, stand A40 at Techtextil 2024) and Verivide (Hall 12, stand A70), both of whom have established strong ties with major producers of technical textiles over many years.

The precise detection of faults during the production of technical fabrics has meanwhile recently been significantly advanced with the introduction of the latest WebSpector automated fabric inspection system by Shelton Vision (Hall 12, stand E54)

Building on its market leading vision system for plain, single colour textiles, Shelton’s patent-pending image processing techniques now recognise and adapt to complex patterns – even those on fabrics with significant distortion and deformation.

Sophistication

Other BTMA members who will be exhibiting at Techtextil 2024 include Avocet (Hall 11, stand B25) the manufacturer of Cetaflam high performance flame retardant (FR) chemicals, Ascotex (Hall 12, stand B41) a specialist in the development and application of yarn guides, and Vandewiele UK (Hall 12, stand D20) the UK arm of Bonas Textile Machinery specialising in high capacity jacquard technology for the weaving industry.

“While sustainability is without doubt driving the agenda these days, there’s always a demand for new feedstocks and fibres that add new functionality, as well as sophisticated new technologies for processing them and exploiting their advantages,” says BTMA CEO Jason Kent. “Techtextil is an essential show for many BTMA members and we see growing opportunities in a number of rapidly expanding markets with exponential growth for our members.”

Founded in 1940, the British Textile Machinery Association actively promotes British textile machinery manufacturers and their products to the world. The non-profit organisation acts as a bridge between its members and the increasingly diverse industries within the textile manufacturing sector.

Note: The content of this press release has not been edited by Fibre2Fashion staff.

Fibre2Fashion News Desk (KD)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)