Interviews

Canadian study offers solutions to apparel microfibres polluting ocean

26 Jul '21

3 min read

Pic: Shutterstock

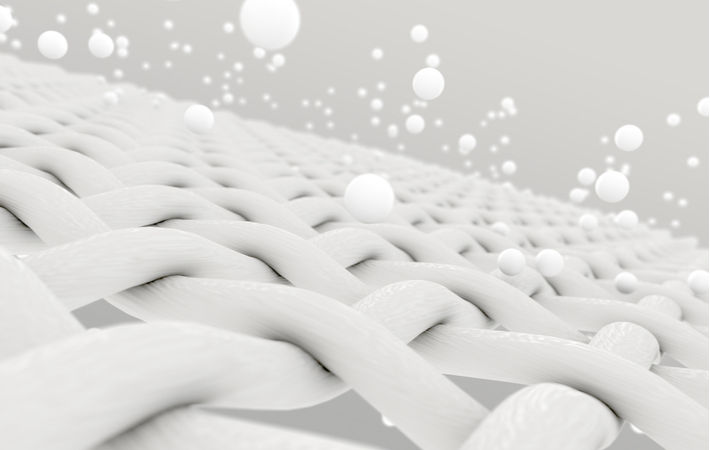

A study by Canada-based Ocean Wise Conservation Association has found it is possible to drastically reduce microfibre pollution through a combination of solutions in home laundry, manufacturing and textile design. The study tested two washing machine lint traps—LINT LUV-R and Filtrol, and found up to 90 per cent of polyester microfibres were captured.

Microfibres—fibres less than 5 mm long—are polluting the world’s oceans and have been found in plankton, seafood consumed by humans, in the stomachs of marine mammals, across the Arctic Ocean and at depths of up to 1,000 metres.

This is a promising opportunity for consumers to take action as well as for washing machine manufacturers to incorporate microfiber capture into product designs to stop the leak of microplastics into the environment, Ocean Wise said in a press release.

The study also points to actions that clothing brands and manufactures can take to reduce microfibre shedding. Most textiles had higher fibre loss in the first laundry cycle, so the Ocean Wise researchers suggest that brands and their suppliers could take action by ‘implementing a wash step for new materials at manufacturing facilities’.

Findings from this research can help guide consumers, clothing brands, textile manufacturers, washing machine producers and wastewater treatment facilities toward implementing impactful interventions to prevent microfibres from polluting oceans.

There is a huge range in shedding rates from different textiles, the study found. The highest shedding materials lost over 800 times more fibres than the lowest shedding materials. This illustrates the strong potential for more sustainable clothing design.

Fleece can be designed to have low shed rates. Although some fleece and mixed fleece textiles had the highest shed rates, there were also some fleeces tested that had quite low shed rates.

Most fibres were typically released in first laundry wash—removing excess fibres at the manufacturing site and exploring design solutions to minimise this waste represent a significant opportunity for apparel companies.

Fibre shedding was positively correlated with fabric thickness for nylon and polyester. Thicker materials are an opportunity for design solutions.

Consumers can also play a role by installing a washing machine lint trap, washing in cold water and only laundering clothes when necessary, the study added.

The study is one of the outcomes of Ocean Wise’s microfibre partnership, a collaboration with the apparel industry and government agencies to find the sources and solutions to the widespread presence of microfibres in the global environment.

The partner organisations that provided Ocean Wise with textile samples and funding for this research include Arc’teryx, Environment and Climate Change Canada, MEC, Metro Vancouver, Patagonia and REI.

Microfibres—fibres less than 5 mm long—are polluting the world’s oceans and have been found in plankton, seafood consumed by humans, in the stomachs of marine mammals, across the Arctic Ocean and at depths of up to 1,000 metres.

This is a promising opportunity for consumers to take action as well as for washing machine manufacturers to incorporate microfiber capture into product designs to stop the leak of microplastics into the environment, Ocean Wise said in a press release.

The study also points to actions that clothing brands and manufactures can take to reduce microfibre shedding. Most textiles had higher fibre loss in the first laundry cycle, so the Ocean Wise researchers suggest that brands and their suppliers could take action by ‘implementing a wash step for new materials at manufacturing facilities’.

Findings from this research can help guide consumers, clothing brands, textile manufacturers, washing machine producers and wastewater treatment facilities toward implementing impactful interventions to prevent microfibres from polluting oceans.

There is a huge range in shedding rates from different textiles, the study found. The highest shedding materials lost over 800 times more fibres than the lowest shedding materials. This illustrates the strong potential for more sustainable clothing design.

Fleece can be designed to have low shed rates. Although some fleece and mixed fleece textiles had the highest shed rates, there were also some fleeces tested that had quite low shed rates.

Most fibres were typically released in first laundry wash—removing excess fibres at the manufacturing site and exploring design solutions to minimise this waste represent a significant opportunity for apparel companies.

Fibre shedding was positively correlated with fabric thickness for nylon and polyester. Thicker materials are an opportunity for design solutions.

Consumers can also play a role by installing a washing machine lint trap, washing in cold water and only laundering clothes when necessary, the study added.

The study is one of the outcomes of Ocean Wise’s microfibre partnership, a collaboration with the apparel industry and government agencies to find the sources and solutions to the widespread presence of microfibres in the global environment.

The partner organisations that provided Ocean Wise with textile samples and funding for this research include Arc’teryx, Environment and Climate Change Canada, MEC, Metro Vancouver, Patagonia and REI.

Fibre2Fashion News Desk (DS)

Popular News

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)