Georgia Tech scientists create energy-harvesting yarns

These fabrics can be sewn into socks, sweaters, and other clothes and then used to harvest energy to charge wearable medical sensors, smartwatches, or cell phones.

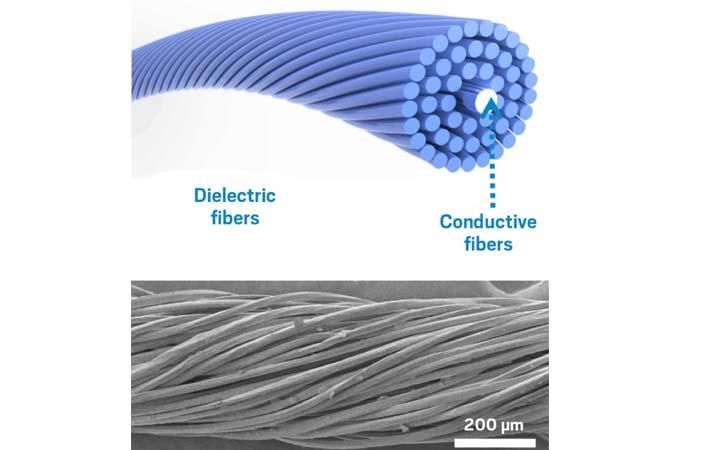

The yarn is based on a device Wang first developed in 2012 called a triboelectric generator, which takes advantage of static electricity that builds up from the friction between two different materials. The design is relatively simple, requiring a conductor (usually a metal) and a dielectric material (often a polymer), in close proximity. Dielectrics are insulators, but static charges can build up on their surfaces.

When the two materials move closer together, electrons jump from the dielectric to the conductor. When they move back apart, those electrons flow into either a capacitor to store the charge or a circuit to generate power. These generators can harvest on the order of tens of milliwatts per square metre. That’s not a lot, but a triboelectric generator the size of a jacket could make 100 mW just from the wearer’s fidgeting—enough to power small sensors or to send a burst of data to receivers a few hundred metres away.

The rub is making a jacket that a person would actually want to wear. Research on energy-harvesting textiles sometimes ignores practical concerns such as breathability, the need of clothing designers to cut and sew it just like any other cloth, and the rigors of the washing machine, Wang says. He realised that he could make triboelectric yarn by covering a thin, flexible stainless steel fibre about 50 micrometer in diameter with a material like polyester or cotton. On the outside of the yarn, “we can substitute any material as long as it’s an insulator,” says Wang.

Wang’s group used machinery from the textile industry to wrap the steel with fibres and to weave the resulting yarn into textiles. These “power cloths” can generate electricity in two ways, he says. As the yarns are stretched and released, the outer insulating layer moves closer to the steel core, then away again, generating a small electrical current. Current is also generated when two layers of cloth—such as the sleeve and body of a sweater—rub against each other. This energy can be captured by a capacitor on the textile or sent over an attached wire to another device.

To test the power-generating potential of these textiles, the researchers sewed a small patch of power cloth made with stretchy Spandex into the sole of a sock and another into the underarm of a sweater. The sock could charge a capacitor to one Volt after about 19 seconds of walking. The cloth works at up to 90 per cent humidity, so it can survive heavy sweating. It also withstood 120 cycles in the washing machine—but it’s line-dry only.

Wang says he’s in contact with industrial partners about commercialising the power cloth for athletic apparel and to charge wearable health monitors. (SV)

Fibre2Fashion News Desk – India

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)