Iowa State University scientists have found a natural way to colour clothing. They have been able to colour fabric using the leftover coffee grounds. The textile industry uses more than two million tons of chemicals and synthetic dyes annually, which pollute the environment. This has led scientific community to work on finding sustainable alternatives.

ISU graduate student in apparel, events and hospitality management, Changhyun “Lyon” Nam, says his coffee habit inspired him to experiment with the grounds. He started by brewing a pot at home and discovered the used beans had potential. “Once I realised it worked, I went to local coffee shops and asked for their leftover grounds,” Nam said.Iowa State University scientists have found a natural way to colour clothing. They have been able to colour fabric using the leftover coffee grounds. The textile industry uses more than two million tons of chemicals and synthetic dyes annually, which pollute the environment. This has led scientific community to work on finding sustainable alternatives.#

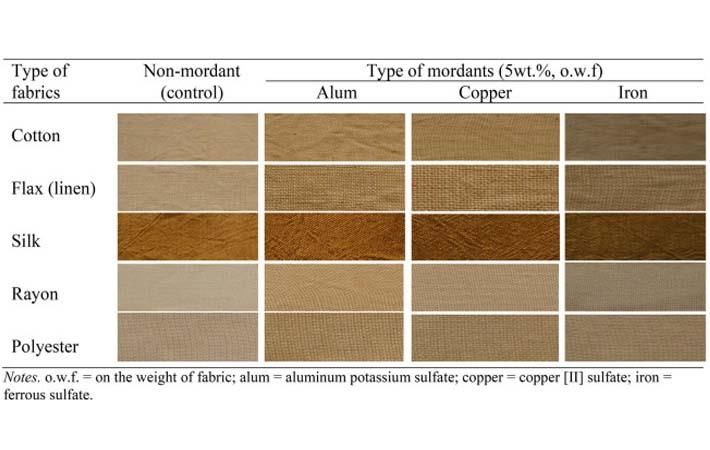

Under the guidance of assistant professor Chunhui Xiang, Nam dried the coffee grounds for three days before boiling them with purified water to extract the dye. He then tested it on cotton, linen, rayon, silk and polyester using different mordants, which help the dye bond to the fabric and, as a result, created a greater variety in shades of brown. The research is published in the International Journal of Fashion Design, Technology and Education.

Limited availability of raw resources increases the cost of natural dyes and limits colour variety, making it necessary to utilise existing materials, Xiang said. Given that 100 million Americans drink a cup of coffee daily, according to the Statistic Brain Research Institute, there is adequate supply, and repurposing the used grounds would divert waste from landfills.

While there are advantages to natural dyes, fading and replicating a consistent colour remain challenging, the researchers said. According to their findings, the mordants reduce fading with the silk, cotton, flax and rayon. However, Xiang says matching the colours produced in the study would be difficult.

“One disadvantage of natural dyeing is that it’s hard to measure the quantity needed to get the exact same colour,” Xiang said. “For each batch of dye, there may be a difference in the type of beans or maybe the coffee was brewed twice. Creating an exact match is a challenge, especially for manufacturers.”

The researchers say more work is needed before natural dyes are a reliable option for mass-production. Nam is now experimenting with the coffee dye and a cellulosic fibre made from kombucha tea to make shoes. Xiang adds that concerns over colour consistency may fade as consumer attitudes change. If there is greater demand for clothing made with natural dyes, consumers may accept the uniqueness natural dyes create.

Fibre2Fashion News Desk (SV)