Scientists at Japan's Riken mimic spider silk with breakthrough device

Insights

- Japanese researchers at Riken have created a device that replicates spider silk production, mimicking a spider's silk gland using microfluidics.

- The silk, known for its strength, flexibility, and lightness, is eco-friendly and suitable for medical uses.

- This breakthrough could revolutionise textile manufacturing and biomedical applications.

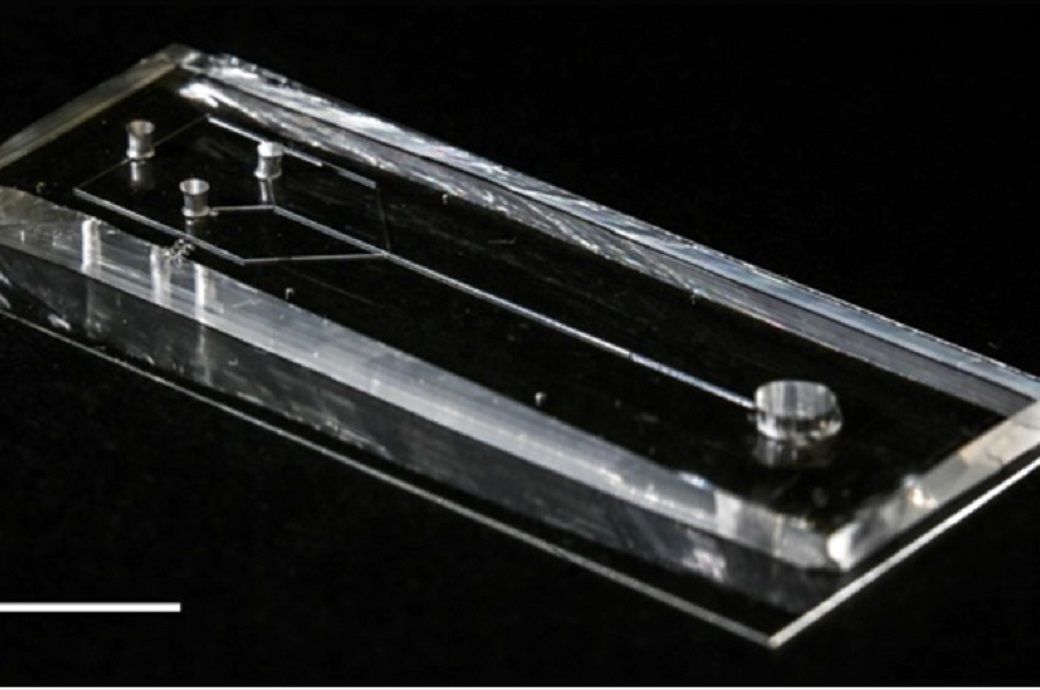

The device developed by the researchers resembles a small rectangular box with microfluidic channels. A precursor spidroin solution is introduced at one end and pulled towards the other using negative pressure. As the spidroins pass through the microfluidic channels, they are exposed to precise chemical and physical changes, facilitated by the microfluidic system's design. Under the optimal conditions, the proteins self-assemble into silk fibres with the complex structure characteristic of natural spider silk, Riken said in a press release.

Spider silk is renowned for its extraordinary strength, flexibility, and lightness, comparable to steel of the same diameter but with an unparalleled strength-to-weight ratio. Additionally, it is biocompatible and biodegradable, making it suitable for various applications, including medicine.

The challenge of large-scale spider silk harvesting from spiders in a practical manner led scientists to seek laboratory production methods. The silk is composed of biopolymer fibres made from large proteins with highly repetitive sequences known as spidroins. Crucially, the molecular substructures within the silk, called beta sheets, must be correctly aligned to achieve the silk's unique mechanical properties.

Rather than attempting to create the process from scratch, the Riken scientists adopted a biomimicry approach. They utilised microfluidics, a technology involving the manipulation of small fluid amounts through narrow channels, to mimic natural spider silk production. The spider's silk gland, in this context, acts as a natural microfluidic device.

Extensive experimentation was conducted to identify the correct conditions, including the interactions among different regions of the microfluidic system. One key discovery was that using negative pressure to pull the spidroin solution was essential for achieving continuous silk fibres with the correct alignment of beta sheets.

The artificial production of silk fibres through this method carries numerous advantages. It has the potential to mitigate the environmental impact associated with current textile manufacturing processes. Moreover, the biodegradable and biocompatible nature of spider silk makes it well-suited for biomedical applications, including sutures and artificial ligaments.

“It was surprising how robust the microfluidic system was, once the different conditions were established and optimised,” said senior scientist Ali Malay, one of the paper’s co-authors. “Fibre assembly was spontaneous, extremely rapid, and highly reproducible. Importantly, the fibres exhibited the distinct hierarchical structure that is found in natural silk fibre.”

Fibre2Fashion News Desk (DP)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)