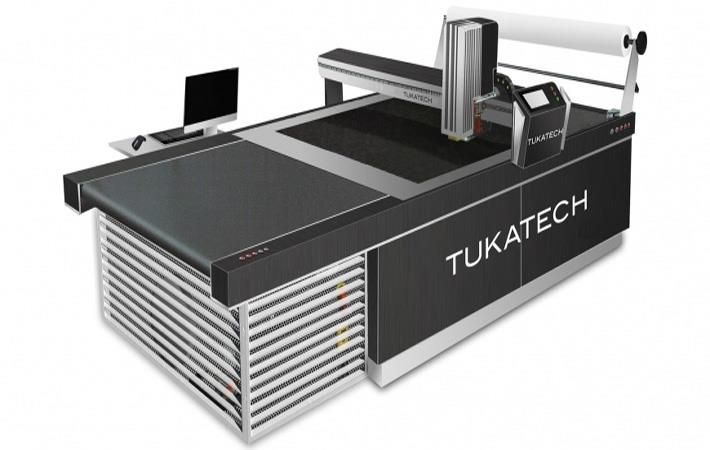

Fashion industry technology leader, Tukatech, has introduced clean air filtration and lowest energy consumption TUKAcut cutting systems, certified by the TÜV SÜD Italia Machine Energy Protocol MEP. The Italian-made machines are customised with Tukatech’s software, and mechanical and electrical specifications to ensure TUKAcut provides an unmatched solution.

TUKAcut machines for lingerie, denim and universal fabric cutting are available in custom widths and heights. These machines are designed to give the ultimate performance at the lowest running cost. Though cutting productivity is at least 20 per cent higher than other models on the market, the energy cost is 50 per cent to 70 per cent lower, which is a great benefit for users in countries where energy cost is a major consideration.Fashion industry technology leader, Tukatech, has introduced clean air filtration and lowest energy consumption TUKAcut cutting systems, certified by the TÜV SÜD Italia Machine Energy Protocol MEP. The Italian-made machines are customised with Tukatech's software, and mechanical and electrical specifications to ensure TUKAcut provides an unmatched solution.#

Other features include the highest productivity per hour cutting denim with zero buffer, as well as a cut path optimiser that results in 2.2 per cent-3.6 per cent fabric savings compared to other cutting machines and helps to increase productivity. The eco-power vacuum system guarantees considerable power savings at only 5.5kw, the lowest in comparable industry cutting machines.

The new fabric cutting machines were first installed in Lahore, Pakistan at Combined Fabrics, the largest supplier of knit garments to Levi’s. Before installation, the cutting room had 90 people cutting 50,000 units in a day. Sheikh Tariq Mehmood, director of Combined Fabrics, explains that the company was already, “very happy users of TUKAcad, TUKA3D, and SMARTmark. Tukatech demonstrated their cutting room expertise by helping us engineer another vendor’s cutting system before we even considered adopting TUKAcut for automatic fabric cutting.”

Implementation included training personnel for raw material handling, spreading, cutting and bundling. On the first day of installation, 14 people were able to cut the same number of units (50,000) and within weeks the same configuration increased productivity to between 65,000 and 75,000 units per day.

Mehmood continues, “My suggestion is to listen to Tukatech’s expertise. Our expectations for the TUKAcut system were exceeded by far, but they never surprised us with extra hidden expenses.” Tukatech is known throughout the apparel industry for their personal customer service and transparent value models.

Ram Sareen, founder of Tukatech, explains that he chose to partner with Italian fabric cutting machine manufacturer, F K Group, to build the TUKAcut systems. Tukatech was the first partner of F K Group to take F K cutting machines out of Italy in 1995. Many of the machines installed in the US, Mexico, Canada, and India at that time are still running and producing high quality cuts. According to Sareen, the partnership with F K Group allows Tukatech to offer garment manufacturers reliable fabric cutting machines at competitive prices. “Similar to engineering companies like AMG partnering with Daimler-Benz to offer an amazingly high-performance vehicle to drivers who appreciate the engineering, we offer just the same with our partnership with F K Group,” comments Sareen. (SV)

Fibre2Fashion News Desk – India