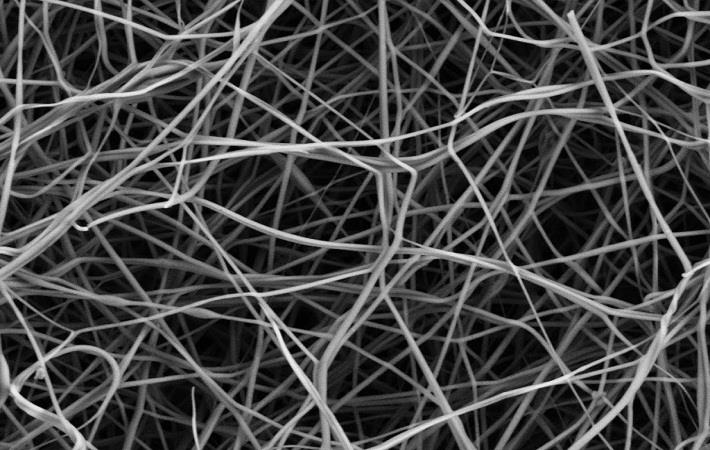

Verdex's patented spinning nozzle technology converts PCC material directly into nano/micro fibres which are blended with larger fibres to form products for the apparel and textile markets. Verdex technology is capable of spinning recycled cleaned PET carpet containing polypropylene and calcium carbonate components. This technology has massive potential in the performance apparel market due the nanofibres producing a much stronger Moisture Vapor Transmission Rate (MVTR) compared to competing products on the market.

The vast majority of carpets are sent to landfills each year, and only around 10 per cent are reused or recycled. In California it is now about 18 per cent, hopefully going to 24 per cent as mandated by the state. This ever growing number represents 2 per cent by weight of American landfill waste, totalling almost 4 billion pounds per year.

"Verdex recycling technology can help alleviate this major problem by taking post-consumer carpet & bottles, and turning these into high value nanofibre media for our customers to enhance existing products or create whole new product lines," said Damien Deehan co-CEO at Verdex Technologies. "We want to make a real impact in contributing to the circular economy. Verdex recycling technology offers its customers a unique opportunity to adopt a recycling element into their finished products, making it good for the environment, our customers and the end user."

Verdex patented technology is a simple, safe process for spinning nanofibres using no solvents – only low pressure air. This provides nonwoven manufacturers the capability to offer a wide variety of functional enhancements to their products containing nanofibres. The Verdex process can also spin nanofibres using polymers such as: PCL, PLA, PP, PET, PBT, Nylon 66, and possible others if melt viscosity is low. The Verdex Process delivers nanofibres in a single step process, which can also incorporate functional particles such as super absorbent powder and activated carbon.

Verdex is currently scaling its core nanofibre technology to a 1 metre commercial line, with its new facility being headquartered in Atlanta, Georgia. The Atlanta facility will also house Verdex's Laboratory scale line, which is available for customers to run tests for new product innovation and development. Verdex is now developing relationships with companies, industries and markets that can benefit from its very unique technologies.

Carpet America Recovery Effort is a non-profit organisation dedicated to increasing the landfill diversion, reuse and recycling of post-consumer carpet through market-based solutions that benefit the economy as well as the environment.

Verdex is a technology company specialising in the production of nanofibres for extensive end use applications including: apparel, performance apparel, textile, air and microfiltration media, high efficiency fuel filtration, advanced filtration, life sciences/pharmaceutical media, acoustics, face masks, hygiene and much more. The company works with apparel and nonwoven companies' to custom develop and manufacture state of the art processes for industry partners wanting proprietary nanofibre technologies.

Fibre2Fashion News Desk (PC)