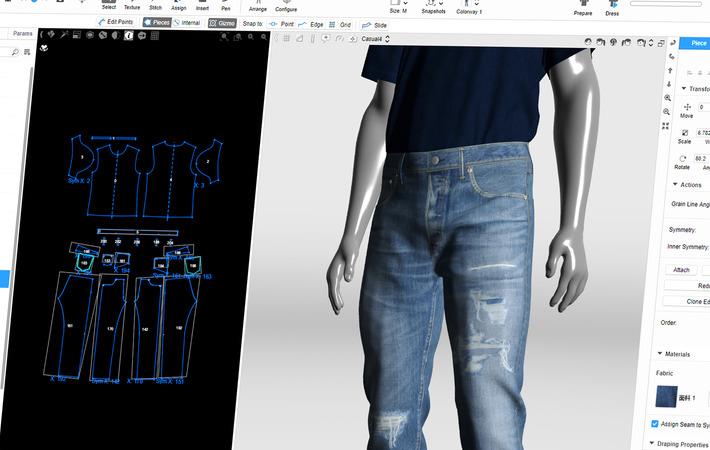

Crystal International Group Ltd, a global leader in apparel manufacturing, has accelerated its digital capabilities and embraced 3D virtual sampling to redesign product development process, from digital design to digital first sample stage. In view of the fast-paced fashion industry, the speed in responding to the latest market trends is the key to success.

Crystal International Group Ltd, a global leader in apparel manufacturing, has accelerated its digital capabilities and embraced 3D virtual sampling to redesign product development process, from digital design to digital first sample stage. In view of the fast-paced fashion industry, the speed in responding to the latest market trends is the key to success.#

In addition to the environmental and economic benefits brought to both customers and the manufacturers, digitalisation allows the manufacturers to produce new designs and styles digitally, speed up sampling process and respond quicker in just a few clicks under prolonged pandemic.

Crystal International Group Ltd, a global leader in apparel manufacturing, has accelerated its digital capabilities and embraced 3D virtual sampling to redesign product development process, from digital design to digital first sample stage. In view of the fast-paced fashion industry, the speed in responding to the latest market trends is the key to success.#

Virtual sampling technology offers versatility and flexibility in today’s digital era. It can significantly speed up lead time by reducing the number of physical iterations needed to go from concept to sale and eventually to production. Logistic time and cost for delivering the physical samples, as well as the production time can be reduced.

Crystal International Group Ltd, a global leader in apparel manufacturing, has accelerated its digital capabilities and embraced 3D virtual sampling to redesign product development process, from digital design to digital first sample stage. In view of the fast-paced fashion industry, the speed in responding to the latest market trends is the key to success.#

Overall, more than 50 per cent time is saved in the product development cycle, which can be shortened to 3 days. With the use of shared end-to-end online platform, all partners in the community including the customers and designers can instantly review, comment and amend the prototypes, which allows efficient and seamless communication.

Crystal International Group Ltd, a global leader in apparel manufacturing, has accelerated its digital capabilities and embraced 3D virtual sampling to redesign product development process, from digital design to digital first sample stage. In view of the fast-paced fashion industry, the speed in responding to the latest market trends is the key to success.#

In addition, digital sampling is an environmentally friendly concept. More than 75 per cent of physical sample as well as associated material, energy and water consumption can be lessened after applying virtual sampling. Waste can be minimised by producing fewer manual samples.

Crystal International Group Ltd, a global leader in apparel manufacturing, has accelerated its digital capabilities and embraced 3D virtual sampling to redesign product development process, from digital design to digital first sample stage. In view of the fast-paced fashion industry, the speed in responding to the latest market trends is the key to success.#

Different product divisions of Crystal International, including denim and knits divisions have embraced virtual sampling in recent years. “We have started to adopt digital sampling technologies since 2017 and it has been gradually accepted by our customers. This demonstrates our sustainability commitment in redefining how we manufacture the jeans. Recently, the trend of digital sampling is particularly accelerated during the times of social distancing. We envision that 80 per cent of our self-developed products are using virtual samples in the product development stage by 2021,” Miles Lam, assistant general manager of product development of Crystal Denim, said in a press release.

Crystal International Group Ltd, a global leader in apparel manufacturing, has accelerated its digital capabilities and embraced 3D virtual sampling to redesign product development process, from digital design to digital first sample stage. In view of the fast-paced fashion industry, the speed in responding to the latest market trends is the key to success.#

“Compared with the same period in 2019, it is astonishing that the number of digital sample remarkably boosted 400 per cent in the first half of 2020. We will strive to produce more in 2021 as we found that virtual sampling can save around 70 per cent of cost for each sampling style and the response time of customers can be elevated by 75 per cent,” My Danny Cheng, general manager of technical services centre of the knits division, said.

Crystal International Group Ltd, a global leader in apparel manufacturing, has accelerated its digital capabilities and embraced 3D virtual sampling to redesign product development process, from digital design to digital first sample stage. In view of the fast-paced fashion industry, the speed in responding to the latest market trends is the key to success.#

Looking ahead, Crystal International anticipates that its virtual samples would account for 90 per cent of its total self-developed product samples and will explore its own digital library for product development process. To bring the best sustainable practices to the sampling process, Crystal International will constantly improve overall efficiency as well as accuracy, and lower production cost while meeting quality standards consistently.

Fibre2Fashion News Desk (JL)