The company is presenting the air-jet spinning machine J 70, ESSENTIALoptimize module of the Rieter Digital Spinning Suite, Ring-Winder-Connect module, ROBOspin, sewing thread finish winder Thread King (third generation) by SSM, Com4recycling system, Card C 81, Supergrinder pro, single-head autoleveler draw frame RSB-D 55, SB-D 55 without autoleveler, doublehead autoleveler draw frame RSB-D 27, and SB-D 27 without autoleveler at the event, Rieter said in a press release.

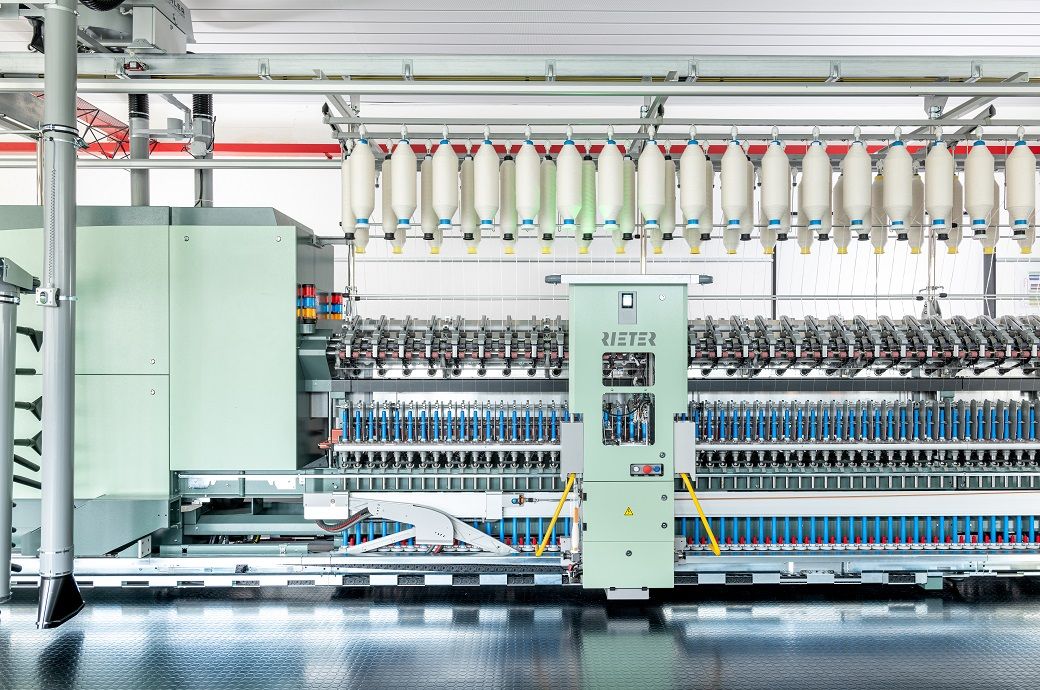

The new air-jet spinning machine J 70 enables spinning mills to achieve an unprecedented low level of production costs per kilogramme of yarn, coupled with high flexibility and reliability. In combination with high productivity, the unique yarn characteristics such as low hairiness and low pilling tendency will contribute to the strong growth of this spinning segment in the coming years.

The new ESSENTIALoptimize module of the Rieter Digital Spinning Suite brings the digital technologist into the spinning mill. It links data from the individual machines and increases efficiency in the entire spinning system.

For instance, the Ring-Winder-Connect module continuously optimises the process between the ring spinning machine G 38 and the winding machine Autoconer X6. This module compares and analyses data from both machines. ESSENTIALoptimize supplies this data in the context of other performance metrics. Ring-Winder-Connect saves valuable raw material and keeps yarn quality within defined parameters.

Rieter has expanded its portfolio in terms of automation. ROBOspin, the industry’s first fully automated piecing robot, is now also available for compact-spinning machines.

SSM has also launched the third generation of the renowned sewing thread finish winder Thread King. The perfect combination of efficiency and sustainability offers considerable added value for customers. Contributing factors are the shorter production cycle, easier yarn thread-up, reduced machine footprint and lower power consumption, added the release.

Sustainable yarns made from recycled fibres are in high demand. Com4recycling is the Rieter system that enables customers to produce fine, high-quality ring and compact yarns from challenging raw material. This holds true even with a relatively high proportion of mechanically recycled cotton fibres.

With both high production rates and excellent sliver quality, the new card C 81 gives spinning mills a strong position in the market. Intelligent sensors make this possible by setting the carding gap to the ideal size and monitoring the contaminant content in real time.

The supergrinder pro, a fully automated single-axis grinding machine, can simultaneously load, check, grind, unload, and sort cots within less than seven seconds. This is made possible thanks to its unique design with an automated tool turret. With a production output of 520 rollers per hour, the supergrinder pro is a must for any spinning mill.

Rieter is launching a completely new generation of draw frames—the single-head autoleveler draw frame RSB-D 55 and the SB-D 55 without autoleveler as well as the doublehead autoleveler draw frame RSB-D 27 and the SB-D 27 without autoleveler. The machines enable spinning mills to achieve the highest quality, productivity, and efficiency, even when processing recycled fibres.

Rieter’s After Sales services provide sustainable repair solutions, upgrades, and performance optimisations to help customers reduce their ecological footprint. Key components from Accotex, Bracker, Graf, Novibra, Suessen and Temco are what make the difference in the economic efficiency of spinning mills, the company said.

Rieter is presenting the latest products at ITMA 2023 in hall 1, booth C206 at Fiera Milano Rho until June 14, 2023. All products will also be on display at the company’s virtual booth. Events led by Rieter experts will also take place at ITMA 2023 every day at 11 am and 3 pm CEST. These events will also be part of the livestream of the virtual trade fair.

Fibre2Fashion News Desk (NB)