In partnership with a number of other companies, for example, ACG Kinna (Hall 9, stand C108) drew considerable crowds to demonstrations of its robotic pillow filling system at the last ITMA show in 2019, TMAS said in a press release.

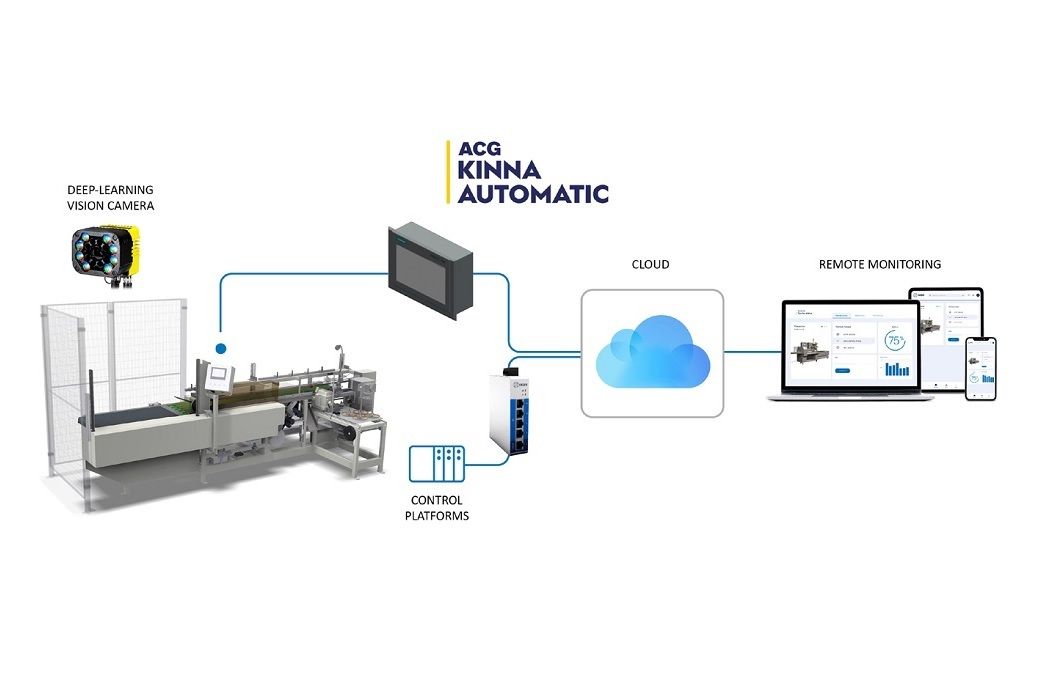

With the ability to fill and finish some 3,840 pillows per eight-hour shift, automated units cover the entire process—from the opening and weighing of the fibre to the filling of the product and on to the sewing and packing processes. The system has been further developed to include new features including an integrated marking solution which allows the customer to print QR codes, batch numbers, and dates on the pillows’ labels, and a unique software for automatically detecting pre-programmed faults which will be introduced in Milan.

“Technologies such as artificial intelligence (AI), machine learning, and automation are becoming increasingly important in the textile industry and in Milan, Swedish companies will showcase new machines and software that can help streamline production and improve efficiency,” said TMAS secretary general Therese Premler-Andersson.

In addition, following its acquisition of the portfolio of Nowo, Kinna is now a single-source supplier of such lines. Nowo’s portfolio of textile production machinery, primarily for fibre processing and quilting, is well established and includes the highly successful Nowo Vac pillow filling system and the Noworoll ball fibre machine.

“The integration of Nowo’s range into our portfolio enables us to now oversee complete projects from start to finish for the highly automated production of pillows, quilts, and other finished products,” said the company’s sales and marketing manager Tomas Aspenskog. “This provides our customers with a number of advantages in terms of transparency and the elimination of bottlenecks. When multiple suppliers are involved in building a line, it can often be difficult for customers to keep them aligned and ensure the construction of one line component is not holding back the completion of others.”

Eton Systems (Hall 9, stand B202) provides automated material handling systems consisting of individually addressable product carriers designed to eliminate manual transportation and minimise handling, radically increasing the time for adding value to garments and other finished items.

These advantages have proven to be a powerful incentive for textile manufactures across Europe and the US to bring some production closer to home, which has been a notable trend in the past few years.

At ITMA 2023, Eton will launch its new software platform, ETONingenious which is a real-time system used to manage, control, and follow up on production in the Eton system. ETONingenious continuously gathers, processes, and presents value-adding product information to operators, supervisors, quality control personnel, and management, added the release.

Utilising the latest development environment, it features a web-based user interface and runs on any browser—laptops, PCs, tablet, and even mobile phones—without any client installation requirements. It is also easy to integrate with any existing ERP system and is industry 4.0 compatible. Dashboards provide a clear and easy overview of production.

“ETONingenious will help companies reach their production targets, freeing up more time for supervisors, reducing throughput time, identifying bottlenecks, and helping to adapt production in real time,” said CEO Jerker Krabbe.

For Premler-Andersson, the AI and advanced automation already being used in a number of ways by TMAS members such as ACG Kinna and Eton have the potential to revolutionise the textile industry, improving production efficiency, quality control, and design processes.

“AI-powered systems can, for example, help detect defects in fabrics and garments during manufacturing processes,” she explained. “By using computer vision in the machinery, different defects such as stains, holes, and uneven stitching can be rapidly identified and corrected at an early stage. Predictive maintenance is another benefit. AI is being used to monitor machines and predict when they are likely to need maintenance. This can help prevent breakdowns and reduce downtime, improving overall efficiency. AI is also proving valuable in R&D for TMAS companies, enabling data from different sources to be coordinated in order to optimise product design and reduce time and costs via the sensor-controlled optimisation of a host of different parameters.”

Fibre2Fashion News Desk (NB)