Lummus & Braskem partner to decarbonise Brazilian site

Insights

- Lummus and Braskem collaborate on a joint study to decarbonise Braskem's site in Brazil using SRT-e electric cracking heater technology.

- The initiative aims to reduce GHG emissions, aligning with Braskem's goal of carbon neutrality by 2050.

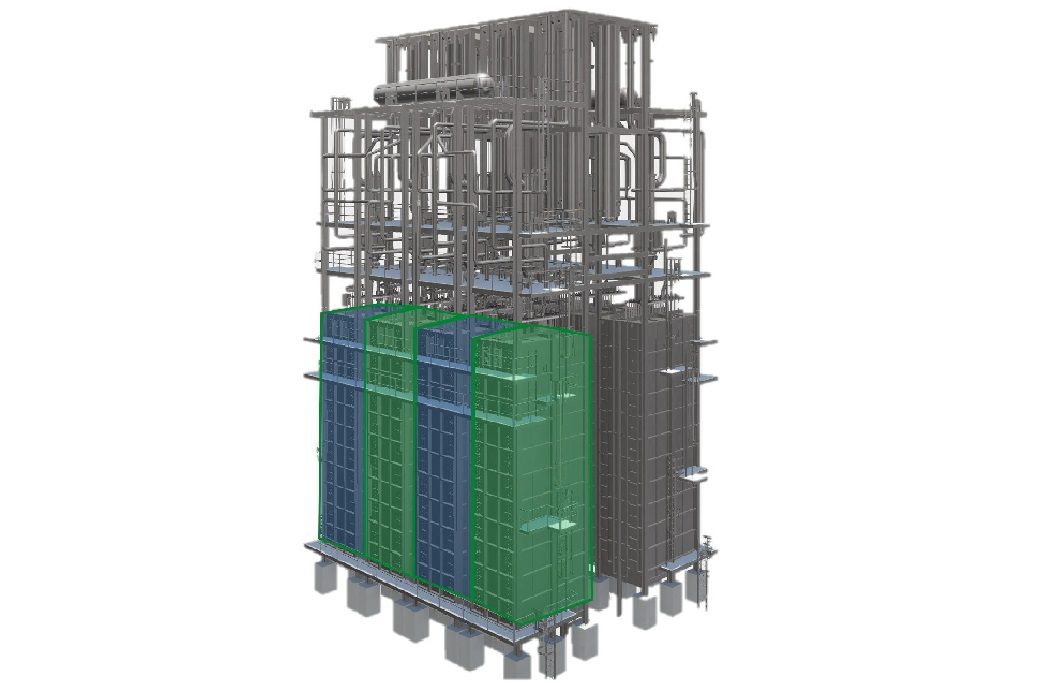

- Lummus' SRT-e technology offers a breakthrough in electrification with modular design and enhanced heat flux profile.

Lummus Technology, a global provider of process technologies and value-driven energy solutions, and Braskem, the largest bio-based polymer producer in the world, announced the companies will carry out joint studies (the "Joint Study") related to the industrial demonstration of Lummus' SRT-e electric cracking heater to decarbonize one of Braskem's sites in Brazil. The Joint Study will set the basis for the eventual negotiation between Lummus and Braskem of a definitive agreement that will, among other things, establish the general guidelines by which such implementation will take place.

"The selection of Lummus' SRT-e electric cracking heater as a means to decarbonize Braskem ethylene plants are founded on a shared commitment to develop and implement profitable sustainable technologies and solutions," said Jose de Barros, vice president and managing director of Ethylene, Lummus Technology. "We look forward to demonstrating our breakthrough electrification technology that drastically reduces greenhouse gas emissions."

The SRT-e electric cracking heater leverages Lummus' proven Short Residence Time (SRT) technology modified to operate using electricity and incorporates a modular unit-cell design that can be replicated for plants to accommodate any commercial capacity. The technology uses all commercially demonstrated components, plus an optimum heat flux profile leading to a longer radiant coil life and longer run length. In addition, decoking can be carried out on a unit-cell basis so maintaining a spare heater is not required.

This initiative is part of Braskem's ambitions to combat climate change, which includes reducing its greenhouse gas emissions by 15 percent by 2030 and attaining carbon neutrality by 2050.

"Our ambition is to considerably reduce CO2 emissions and increase the sustainability of our products through innovation, in-house developments, and important partnerships. Lummus' SRT-e technology will help Braskem achieve its goal of carbon neutrality by 2050, which will help increase energy efficiency at our crackers," said Antonio Queiroz, Braskem VP for Innovation, Technology and Sustainable Development. "Expanding the use of renewable electricity and renewable materials will enable Braskem to reduce its carbon footprint in the production of ethylene, propylene and other chemicals."

Lummus has supplied heat transfer equipment and systems to the process and power industries for more than 80 years. Specializing in heat transfer solutions and systems for critical process environments, Lummus has produced industry-leading technology for fired heaters, including the Short Residence Time (SRT) pyrolysis furnace, and heat exchangers, including the HELIXCHANGER heat exchanger and LABLEX and Polaris Lummus advanced breech-lock exchanger.

Note: The content of this press release has not been edited by Fibre2Fashion staff.

Fibre2Fashion News Desk (HU)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)