Sedo Treepoint will show intelligent manufacturing solutions from Sedo Treepoint supporting digitalisation of textile industry at ITMA Asia + CITME 2018 expo, hall 6, A17. The exhibition will be held from October 15-19, 2018 in Shanghai, China. Sedo Treepoint is a leader for digital systems for textile finishing automation and software systems.

Today, the textile industry is facing an environment that is influenced by technological shifts, economic changes and fast-changing consumers’ trends. Many countries have responded with strategies that should transform the industry: Germany has Industry 4.0, China Made in China 2015, the US the Industrial Internet Consortium, just to name a few.Sedo Treepoint will show intelligent manufacturing solutions from Sedo Treepoint supporting digitalisation of textile industry at ITMA Asia + CITME 2018 expo, hall 6, A17. The exhibition will be held from October 15-19, 2018 in Shanghai, China. Sedo Treepoint is a leader for digital systems for textile finishing automation and software systems.#

For companies it will be challenging to remain with traditional business models. Complexity is rising anyway so sticking to old patterns will not be the solution. Environmental regulations and customer demands are putting additional pressure for more sustainable solutions. Companies need open- minded leaders with a long-term plan, investing in information technology and IT-skills for their team, the company said in a press release.

To raise the competitiveness, intelligent manufacturing will lead to a more efficient production and higher quality.

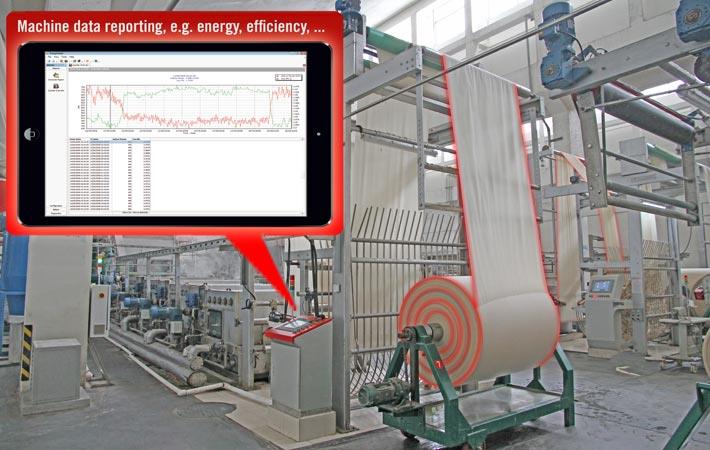

Sedo Treepoint’s technology is the core for digitalisation, not only for the textile dyeing and finishing, but also for other departments like spinning, weaving, and knitting. An integrated system can be build up that does not stop at production management, but also includes colour management. The build-in intelligence of the production planning, simulation, and colour management can save high amount and will increase sustainability remarkably. EnergyManagment by EnergyMaster will give you the tools to dig deeper into Energy Consumption and to set higher goals for savings.

Processes can be shortened and daily batch production increased significantly. Included routing functions will tell you at a push of a button on which machine the fabric is in process and will support determining capacity requirement and schedule production activities. Beyond the integration of the dyeing department, it is also important not to stop here. Continuous processes are next to be integrated in an overall company system. Having valuable machine data, business intelligence for manufacturing is giving customers important key data for a shift leader, operation manager, technician, management, or machine operators. No need to rely on unproved statements like ‘Machines type B the most sustainable type’.

Production related reports show the reality: Water consumption per kg fabric or yarn, power consumption for a kg of dyed knitted fabric, and so on. Some managers are astonished about their findings and get a real picture of what is going on. (GK)

Fibre2Fashion News Desk – India