Interviews

Groz-Beckert shows litespeed knitting needles at ITMA Asia

16 Oct '18

2 min read

Courtesy: Groz-Beckert

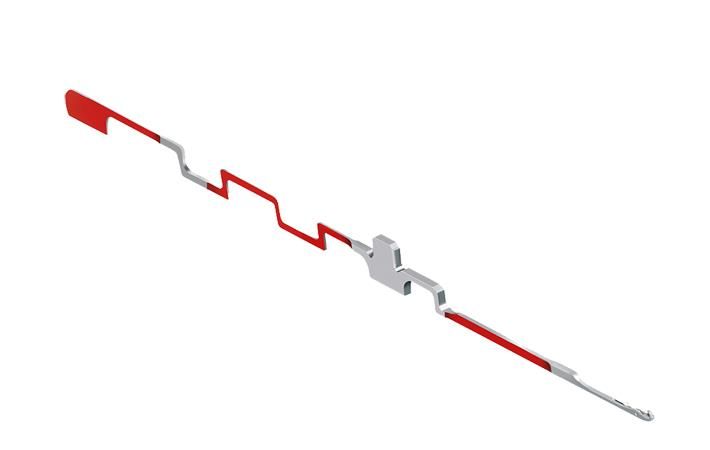

Groz-Beckert, a provider of industrial machine needles, precision parts, and fine tools for textiles, is showing its new litespeed needles for high performance circular knitting machines, at the ongoing ITMA Asia + CITME 2018 expo, in booth D25, hall 4. The international textile machinery expo is being held from October 15-19, 2018, in Shanghai, China.

The litespeed plus is a further development of the proven litespeed technology. It reduces energy consumption and the machine temperature even further – by up to 20 or 17 per cent, for a noticeable reduction in costs, Groz-Beckert said in a press release.

In the dimensions relevant for loop formation, the litespeed plus needle corresponds exactly to a conventional needle for circular knitting machines. The difference lies in the optimised shaft geometry: Thanks to a partial reduction of the needle shaft thickness on both sides, the needle can be inserted irrespective of the machine direction. The weight and the friction of the needle in the needle trick is also reduced. Both have a positive impact on the flow characteristics of the needles in the cylinder.

The reduction of the contact surface through the reduced shaft thickness of the litespeed plus on both sides leads to a lower level of friction between the needle and cylinder. This means that less energy is required for the needle movement, which can help to reduce the energy consumption in the knitting process by up to 20 per cent. This not only reduces the energy consumption, but also helps to achieve a significant reduction in CO2 emissions.

In practice, extremely high temperatures can be achieved on cylinders and cam parts in modern (high-performance) circular knitting machines. This inevitably leads to problems during the needle and sinker change. In extreme cases, this can even limit the speed performance of the machines. The reduced needle shaft thickness of the litespeed plus reduces the friction between the needle and cylinder and improves the lubrication behaviour, which can reduce the temperature at maximum machine speeds by up to 17 per cent. The partially reduced needle shaft thickness enables better distribution of the needle oil in the needle trick. For the knitting machine, this means: lower machine temperature, reduced oil consumption and less oil nebulisation. (GK)

The litespeed plus is a further development of the proven litespeed technology. It reduces energy consumption and the machine temperature even further – by up to 20 or 17 per cent, for a noticeable reduction in costs, Groz-Beckert said in a press release.

In the dimensions relevant for loop formation, the litespeed plus needle corresponds exactly to a conventional needle for circular knitting machines. The difference lies in the optimised shaft geometry: Thanks to a partial reduction of the needle shaft thickness on both sides, the needle can be inserted irrespective of the machine direction. The weight and the friction of the needle in the needle trick is also reduced. Both have a positive impact on the flow characteristics of the needles in the cylinder.

The reduction of the contact surface through the reduced shaft thickness of the litespeed plus on both sides leads to a lower level of friction between the needle and cylinder. This means that less energy is required for the needle movement, which can help to reduce the energy consumption in the knitting process by up to 20 per cent. This not only reduces the energy consumption, but also helps to achieve a significant reduction in CO2 emissions.

In practice, extremely high temperatures can be achieved on cylinders and cam parts in modern (high-performance) circular knitting machines. This inevitably leads to problems during the needle and sinker change. In extreme cases, this can even limit the speed performance of the machines. The reduced needle shaft thickness of the litespeed plus reduces the friction between the needle and cylinder and improves the lubrication behaviour, which can reduce the temperature at maximum machine speeds by up to 17 per cent. The partially reduced needle shaft thickness enables better distribution of the needle oil in the needle trick. For the knitting machine, this means: lower machine temperature, reduced oil consumption and less oil nebulisation. (GK)

Fibre2Fashion News Desk – India

Popular News

Leave your Comments

Editor’s Pick

Dr. Michael Duetsch & Man Woo Lee

UPM Biochemicals and Dongsung Chemical

Durga Prasad Chalavadi

Sai Silks Kalamandir Ltd

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)